CEGRIT Automatic Flyash Sampler

Benefits of using the CEGRIT flyash sampler

Thank you for your interest in the CEGRIT Automatic Flyash Sampler. With no moving parts, each CEGRIT fly ash sampler collects a sample from one point in the boiler duct. Operating on duct vacuum to drive its atmospheric-air ejector, the CEGRIT maintains near-isokinetic sampling to keep collecting unbiased sample as boiler load and duct vacuum vary.

The CEGRIT kit is supplied with basic sampling system, 110-volt heater jacket (if appropriate; see below), probe, inlet nozzle, and sample jars. This is everything you need to start sampling immediately. At least 1” WG draft [negative duct pressure] is normally needed (if duct pressure is positive an adapter is available for an additional charge and requires a tiny amount of plant compressed air), and flue gas temperature at the sampling point can be up to 1000°F — either upstream or downstream of an air preheater. When you install your sampler, the ejector nozzle area is easily adjusted to establish isokinetic flow, using a water manometer (not supplied) or other differential pressure measuring device temporarily to indicate flow through the CEGRIT.

The CEGRIT sampler collects fly ash samples that are constantly available for visual inspection by operating personnel and for laboratory analysis. Your CEGRIT samplers can help you achieve the following benefits:

- Assess mercury capture by flyash

- Optimize combustion for minimum NOx emissions

- Save fuel by minimizing excess air while controlling carbon losses

- Produce high-quality flyash for sale

- Minimize labor involved in routinely sampling flyash

- Avoid sample bias and time lag involved in hopper or ash-line sampling

Since the CEGRIT was invented in England in 1962, thousands of these flyash samplers have been installed worldwide. For a partial list of users, click here.

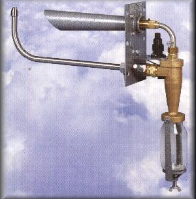

Cegrit is the closest thing there is to a “perpetual motion machine.” Refer to the photo above to see how it works. In this configuration the flue gas flow is downward, but Cegrit can accommodate flow up, down, left, or right. It must be mounted on a vertical surface.

The horn-like cone at the top of Cegrit extends into the flue gas duct. When the duct is under negative pressure, atmospheric air from outside the boiler flows into the horn, and its flow rate is tailored to isokinetic sampling by adjusting the nozzle at the end of the curved tube at the top of the cyclone, with the help of the Cegrit calibration curve.

Flue gas and flyash flow into the sampling probe at left. The cyclone at the end of that probe separates ash from flue gas, and the ash flows by gravity into the glass jar to be viewed (“see the grit”) or taken for laboratory analysis. The cleaned flue gas returns to the duct through the conical “horn.”

When used on a negative-pressure duct, Cegrit’s atmospheric air aspirator accomplishes the sampling with no energy input — that’s why we call it a perpetual motion machine. When there’s positive pressure in the duct, an optional special curved tube at the cyclone exit enables Cegrit to sample using a small amount of plant compressed air to drive the ejector.

The spelling “Cegrit” came from the initials of Cegrit’s developer, Britain’s Central Electricity Generating Board. That organization no longer exists, but Cegrit has been in commercial use by coal-burning plants worldwide since 1962.

For a Cegrit parts diagram and parts list, click here. Click here for suggested installation instructions for your Cegrits. For setup only, you’ll need a Pitot probe with manometer to use temporarily to adjust the CEGRIT ejector nozzle. These aren’t supplied with the CEGRIT since most customers already have them available in-house for temporary use.

Click here for more information about ordering a CEGRIT flyash sampler

More information on the CEGRIT can be obtained in 'pdf' format by clicking here. However, contrary to the temperature maximum stated there, today's Cegrit can operate in flue gases up to 1000°F (538°C).

CEGRIT without its probe. In this case the configuration is for upward gas flow, and the cyclone is heated because installation is downstream of air preheater. However, flow can be upward, downward, or horizontal (after a simple adjustment). Cegrit must be mounted on a vertical wall so that gravity enables the cyclone to function.

MISSION INSTRUMENTS

subsidiary of

Sotter Engineering Corporation

Contact: John Sotter

26705 Loma Verde

Mission Viejo, CA 92691-6055 USA

Phone: 949-933-6971

Email: john@safetydirectamerica.com